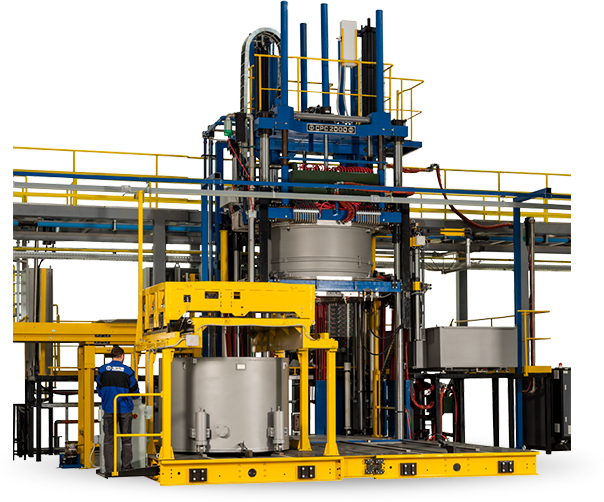

The CPC 2200 is our flagship model and one of the most advanced counter pressure casting machines on the market.

With an expanded envelope and reinforced frame, it is specifically designed to handle the most complex, large-format aluminum castings—perfect for electric vehicle platforms, full chassis modules, and safety-critical components. Equipped with integrated cooling control, intelligent automation, and real-time process monitoring, the CPC 2200 enables industry-leading performance with maximum uptime. This machine redefines scalability and capability for modern casting production.

CPC 2200

The CPC 2200 stands at the pinnacle of counter pressure casting technology as CPC’s largest and most advanced machine, purpose-built to produce the industry’s most complex and oversized aluminum components

Designed to meet the demands of next-generation mobility and industrial engineering, the CPC 2200 delivers unmatched strength, scale, and casting performance for foundries that lead the market in structural innovation.

More details

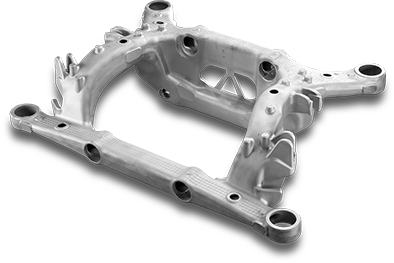

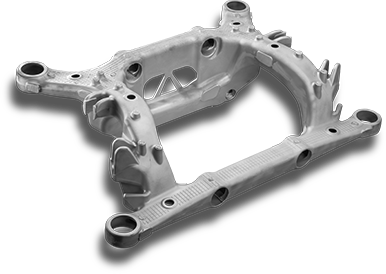

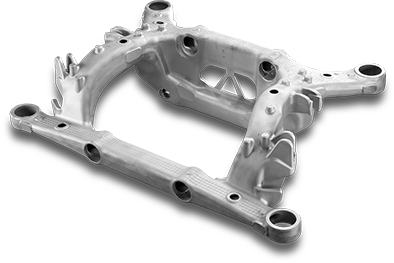

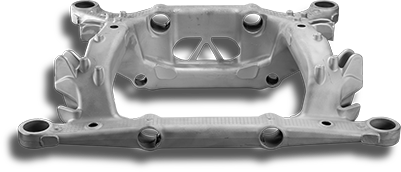

As the premier model in the CPC lineup, the CPC 2200 is engineered for ultra-large castings such as full chassis modules, EV battery trays, heavy-duty suspension parts, subframes, and high-load industrial housings. With its expanded mold capacity, increased clamping force, and robust construction, the machine is ideally suited for single-cavity production of massive structural parts where dimensional stability, mechanical integrity, and where mechanical properties are critical.

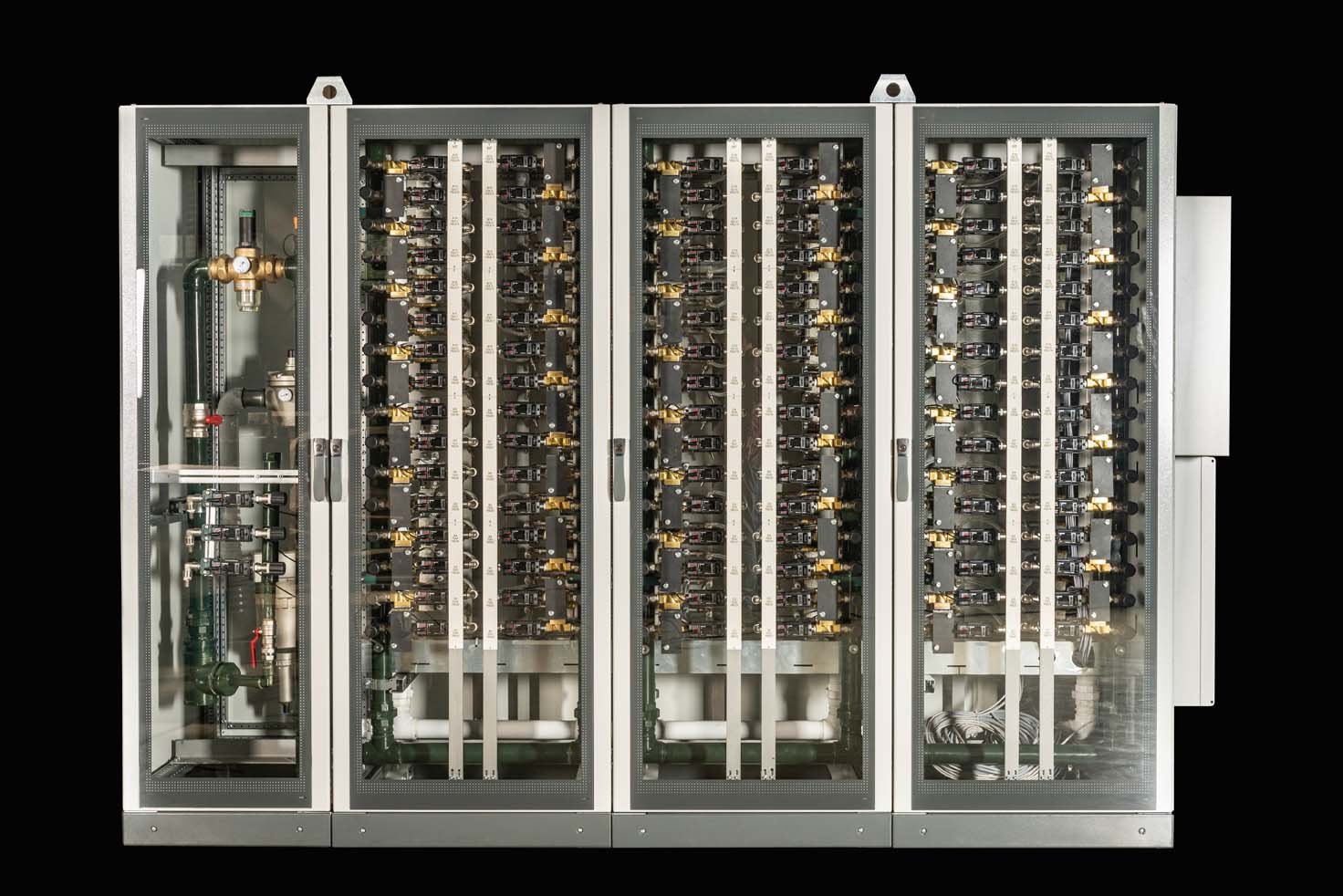

Built with the flexibility to integrate between 16 and 128 cooling lines, the CPC 2200 ensures precise thermal control for each specific casting geometry—supporting optimal solidification, reduced porosity, and consistent surface finish even on the most demanding part profiles. This level of cooling precision is essential when casting components with varying wall thicknesses or complex internal features.

At its core, the CPC 2200 harnesses the proven Counter Pressure Casting (CPC) process, which uses a controlled pressurized environment to deliver castings with significantly improved mechanical properties, minimal turbulence during mold fill, and drastically reduced gas entrapment. These benefits translate into stronger, lighter, and more reliable components that meet the highest standards in performance, safety, and durability.

Like every CPC machine, the 2200 is built on a foundation of reliability, accuracy, and intelligent foundry automation. The system architecture includes adaptive control logic, real-time process monitoring, and seamless integration into high-volume production environments—making it a top choice for OEMs and Tier 1 suppliers worldwide.

With its scalability and versatility, the CPC 2200 is utilized across a wide range of sectors including automotive, aerospace, marine, medical, electrical, and heavy industrial applications. It is the ideal solution for foundries looking to produce large-format, high-strength aluminum castings with repeatable precision and the lowest possible scrap rates.

For manufacturers pushing the boundaries of aluminum casting, the CPC 2200 offers the ultimate combination of size, strength, and performance—a machine built to shape the future of structural casting.

Features

- Counter Pressure Technology

- Single to Multi Cavity Mold

- 32-128 Cooling Lines

- Siemens/Allen Bradley HMI

- Holding Furnace: 1200kg

- Sand Cored Part Capability

- Thin Walled Parts

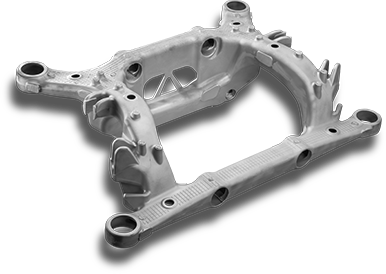

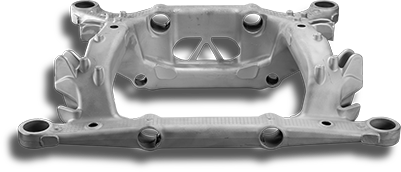

- Typical Parts : Large Structural Chassis Components , Subframes, Battery Tray, etc

Typical 2200 Parts

Large Structural Chassis Components I Subframes I Battery Tray

Need help finding the right machine?

If you would like more information about how a new CPC machine can bring your products to life, please contact us.