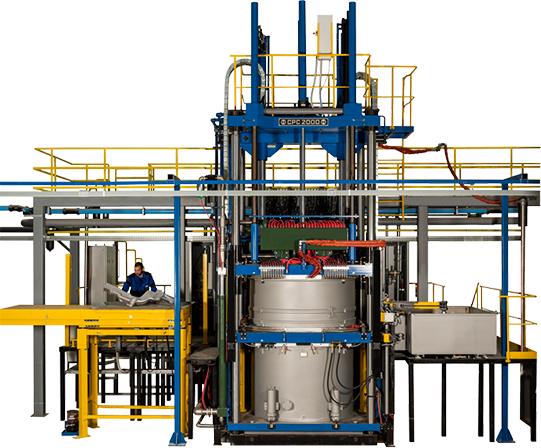

The CPC 2000 is a high-performance casting machine tailored for the production of demanding large aluminum structural components. With increased mold size capacity and it delivers unmatched consistency and mechanical properties on large parts.

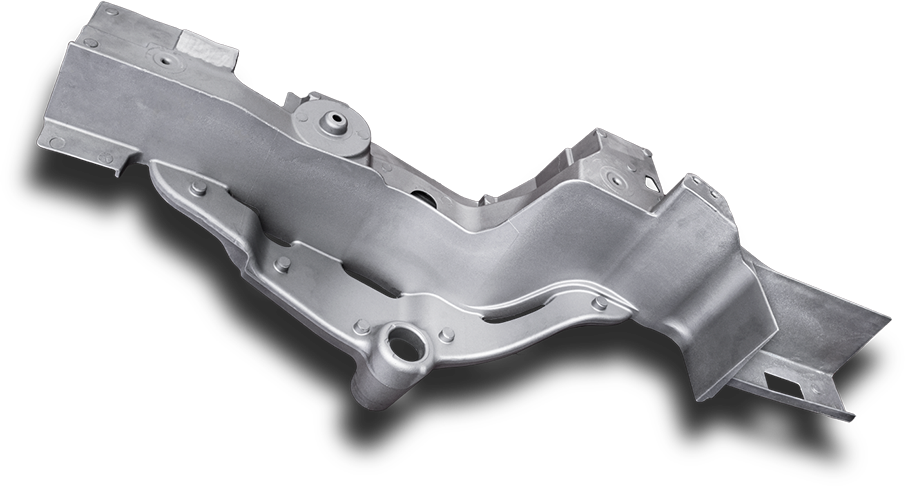

Whether producing subframes, battery housings, or suspension arms, the CPC 2000 ensures reduced porosity and higher yield rates through its refined pressure control and optimized filling profiles. It is the workhorse of high-volume OEM production environments looking for reliable, repeatable results.

CPC 2000

The CPC 2000 represents the next evolution in large scale aluminum casting, offering expanded capacity and power while maintaining the flexibility and technological advantages found throughout the CPC machine family.

As a step up from the CPC 1800, the CPC 2000 is purpose-built for manufacturers producing larger and more structurally demanding components without sacrificing speed, reliability, or process control.

More details

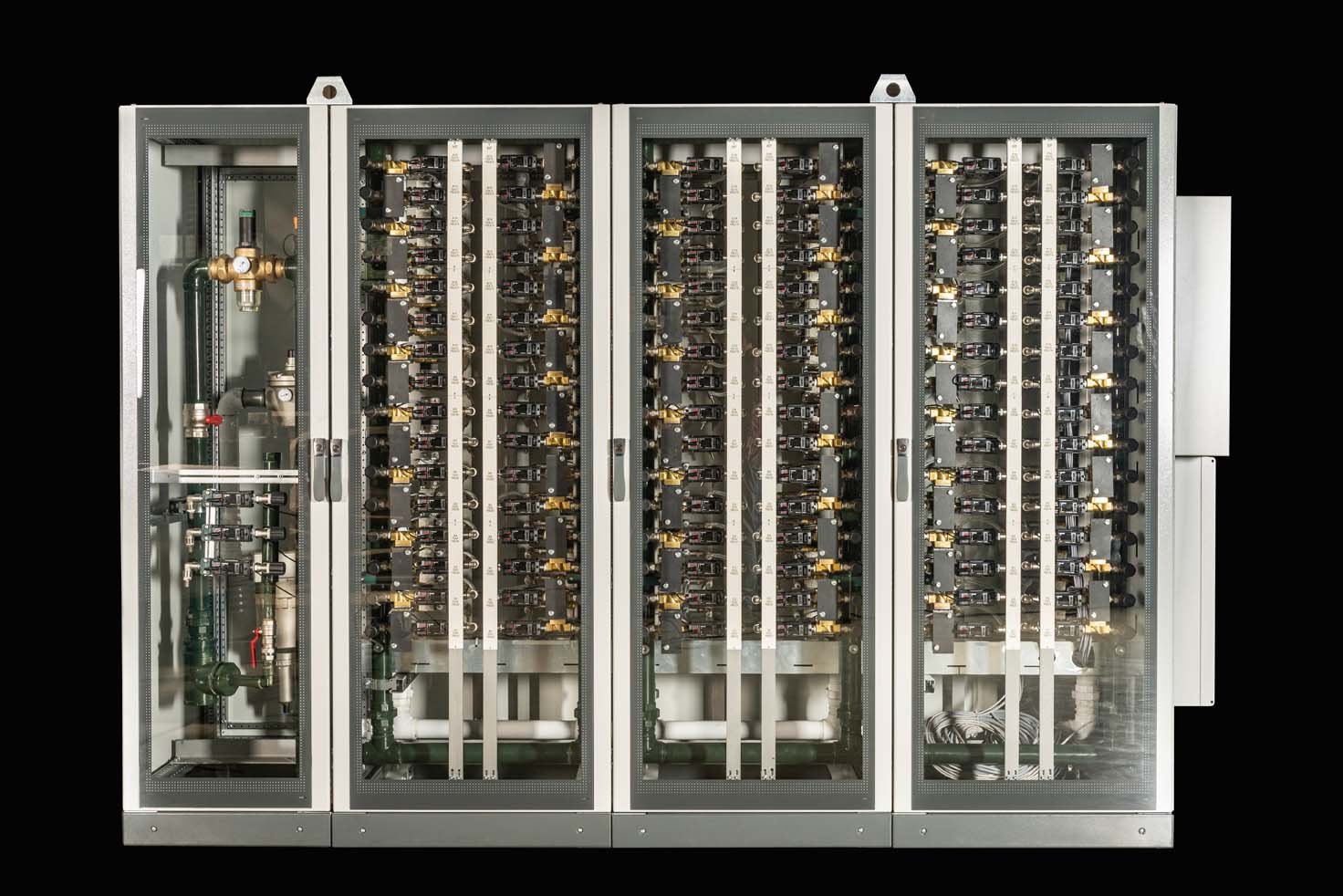

Engineered for strength and scale, the CPC 2000 is ideal for the production of large structural parts such as subframes, crossmembers, battery housings, and industrial enclosures. Its enhanced clamping force and mold size capacity make it a powerful platform for single-cavity structural castings, while still being capable of multi-cavity configurations when higher volumes are required. With a cooling system that supports 16 to 128 integrated cooling lines, the CPC 2000 allows complete thermal management customization—ensuring faster solidification, improved surface quality, and reduced cycle times.

At the heart of the CPC 2000 is the Counter Pressure Casting (CPC) process, renowned for its ability to produce castings with superior mechanical properties, lower porosity, and exceptional consistency. This results in stronger, lighter, and more dimensionally stable components, enabling advanced designs and reducing the need for secondary operations. Whether the end-use is safety-critical automotive structures or high-performance industrial parts, the CPC 2000 delivers exceptional casting integrity.

Like all CPC systems, the CPC 2000 is engineered with the highest standards of durability, precision, and intelligent automation. Its robust mechanical design, modular software controls, and seamless integration into foundry environments make it a trusted asset in large-scale production lines.

The CPC 2000 is widely used across multiple sectors, including automotive, marine, aerospace, medical, electrical, and heavy industrial manufacturing, offering unmatched production versatility for manufacturers with varied and complex casting requirements.

Whether scaling up from a smaller model or seeking to expand production capabilities into larger, more complex castings, the CPC 2000 delivers the power, precision, and flexibility to lead in the most demanding markets.

Features

- Counter Pressure Technology

- Multi Cavity Mold

- 32-128 Cooling Lines

- Siemens/Allen Bradley HMI

- Holding Furnace: 1200kg

- Sand Cored Part Capability

- Thin Walled Parts

- Typical Parts : Large Structural Chassis Components , Cross Members, Subframes

Typical 2000-S Parts

Large Structural Chassis I Components I Cross Members I Subframes

Need help finding the right machine?

If you would like more information about how a new CPC machine can bring your products to life, please contact us.