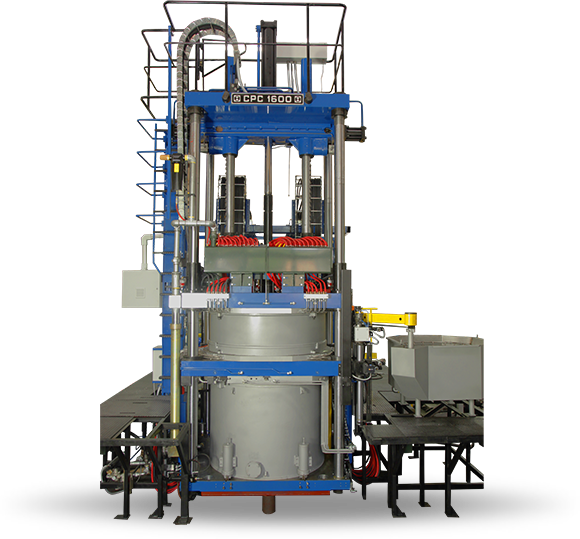

Renowned worldwide for its outstanding performance, the CPC 1600 is specifically engineered for high-volume production of small to mid-size chassis components.

This advanced machine combines exceptional speed and multi-cavity versatility, to deliver unparalleled efficiency and precision in safety critical aluminum castings.

CPC 1600

The CPC 1600 series is the most popular and widely used machine in our lineup, trusted by leading manufacturers across the globe.

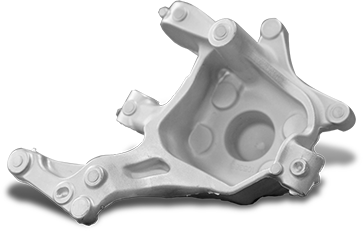

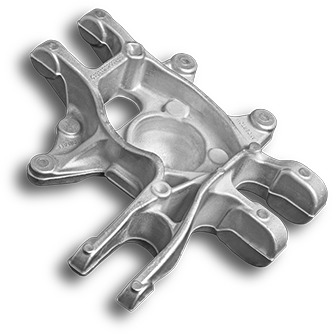

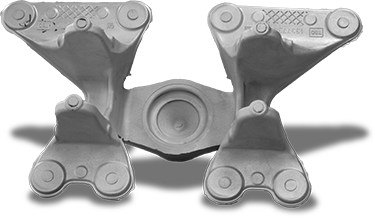

Known for its versatility, productivity, and compact footprint, the CPC 1600 is engineered to deliver exceptional casting performance for high-volume structural components—most notably, front and rear knuckles, with tens of millions of parts produced annually using this model.

More details

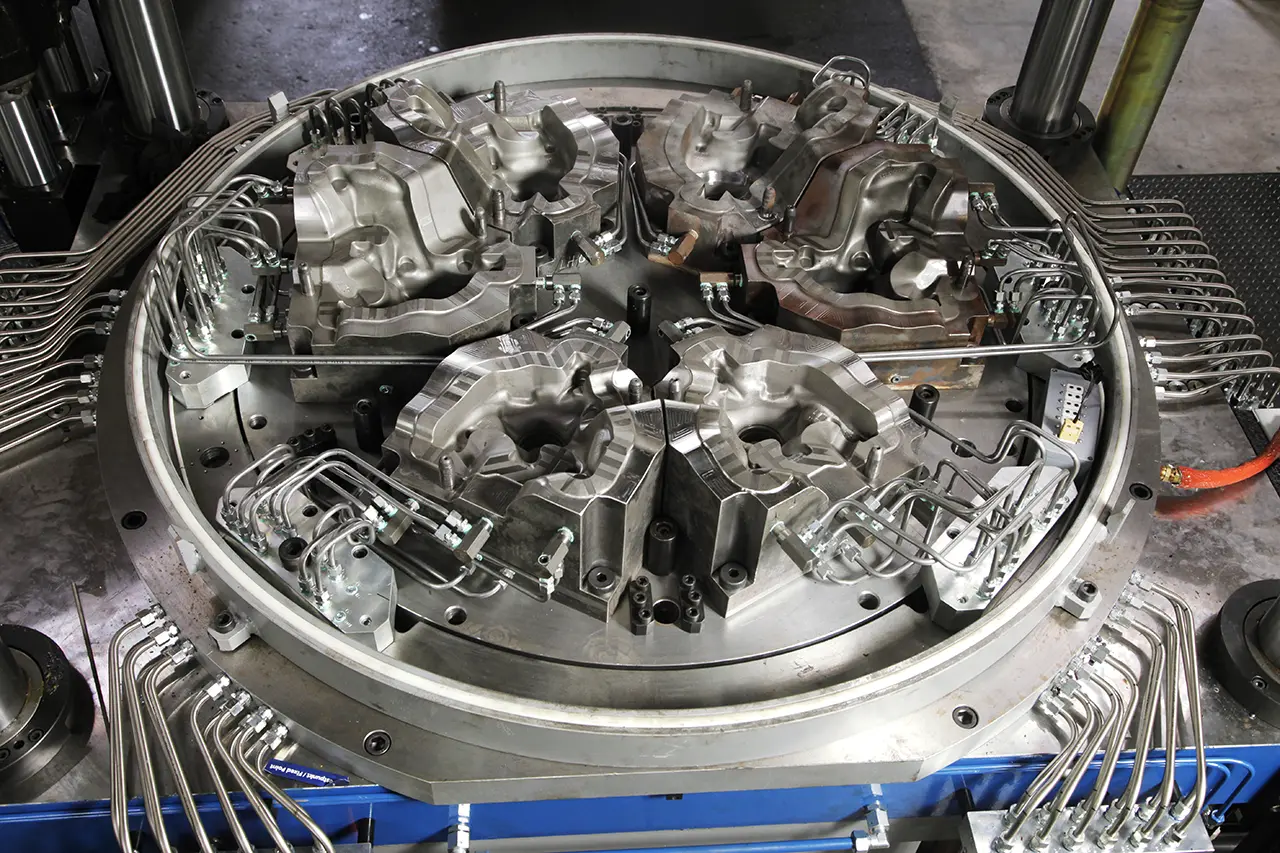

Designed as a 6-cavity powerhouse, the CPC 1600 offers unmatched output in a highly efficient package. Its flexible architecture supports both multi-cavity and single-cavity production, making it ideal for foundries seeking to optimize space, reduce cycle times, and increase throughput without sacrificing casting integrity.

The CPC 1600 series includes four distinct models, each tailored to meet specific casting requirements and production volumes while maintaining the same high standards of performance and reliability.

Backed by over two decades of counter pressure expertise, the CPC 1600 integrates all the hallmarks of CPC’s advanced engineering:

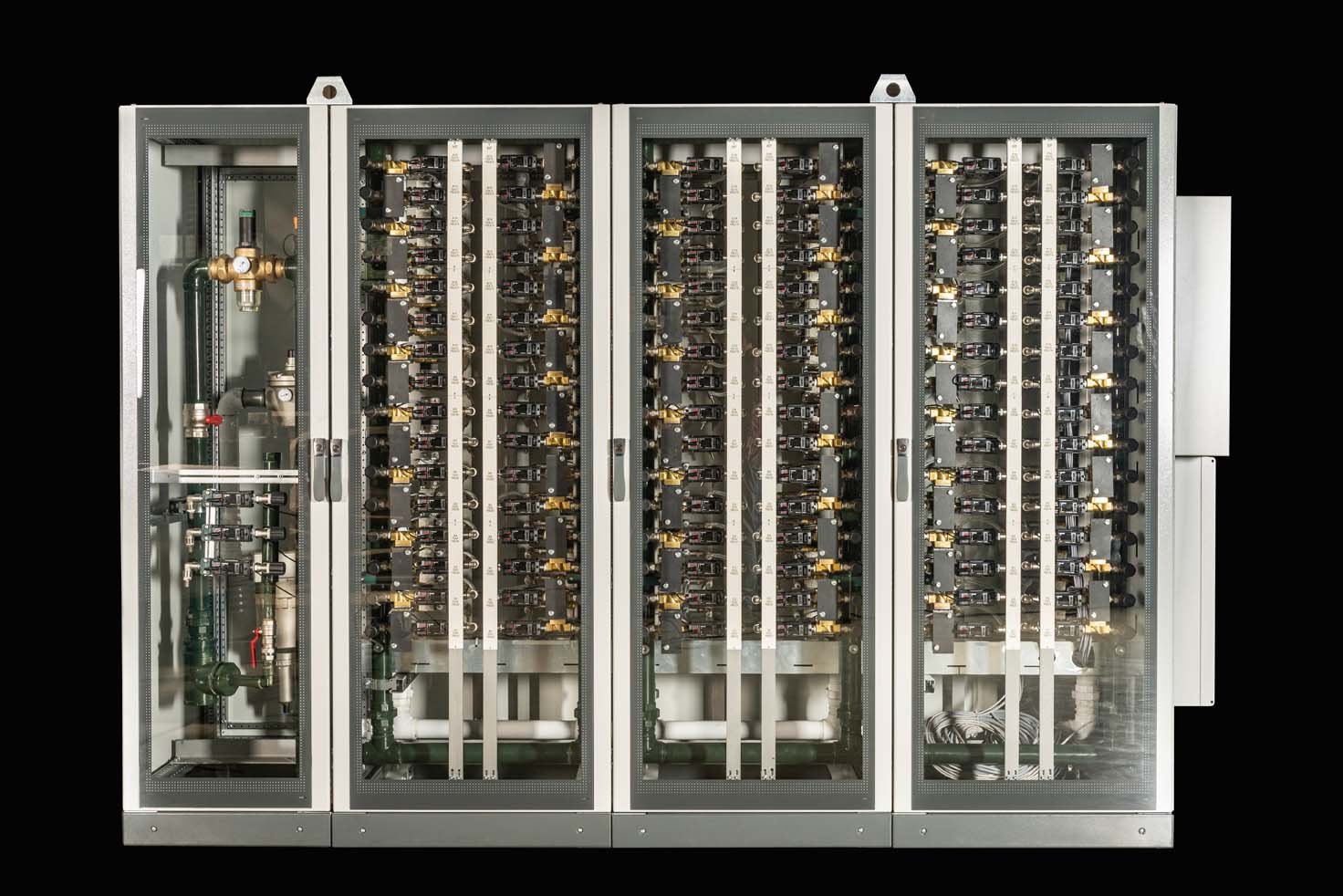

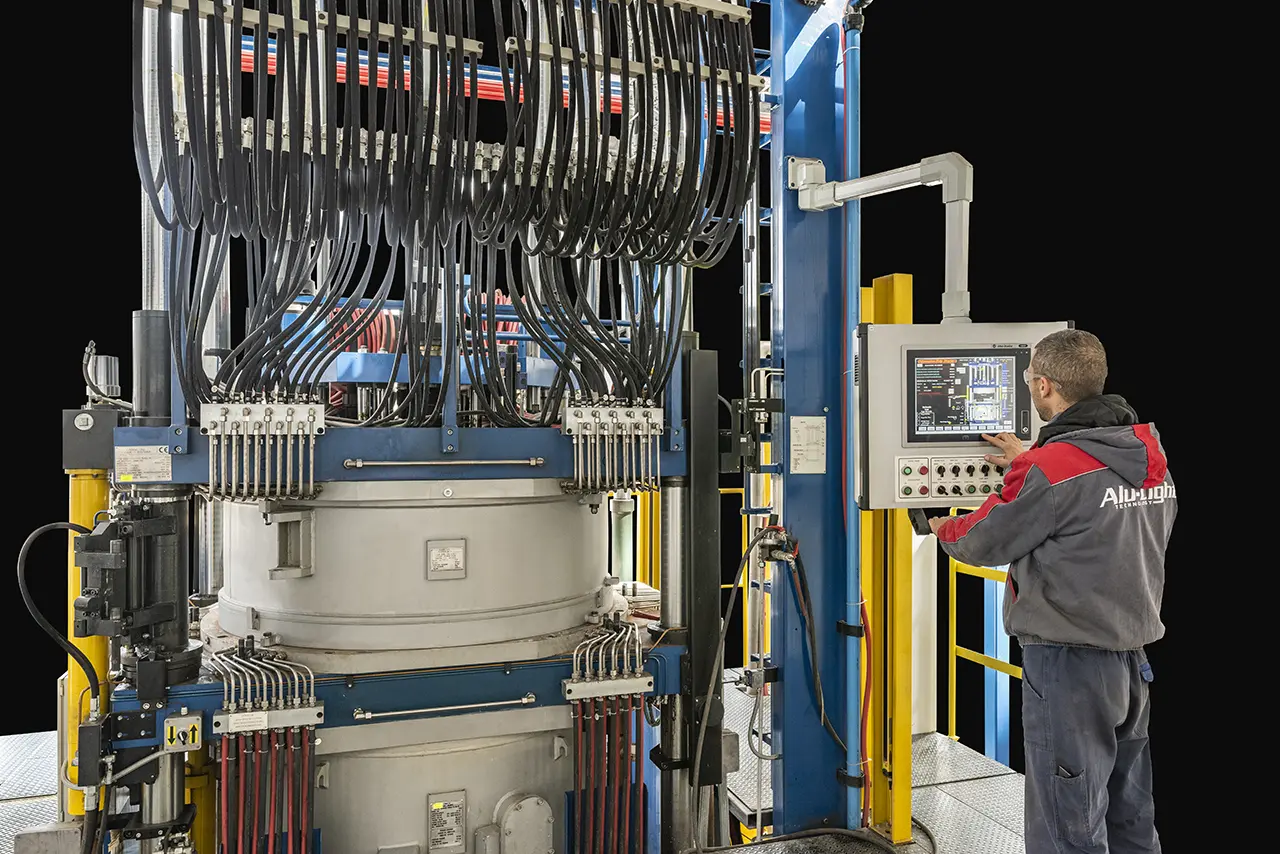

- Support for up to 96 cooling lines for thermal accuracy and rapid solidification

- Real-time process control and adaptive automation

- And of course, our proprietary Counter Pressure Casting process, which ensures superior mechanical properties, reduced porosity, and repeatable part quality

With installations in some of the world’s most demanding OEM and Tier 1 production lines, the CPC 1600 series has become the go-to solution for safety-critical and performance-driven aluminum castings. Its robust construction and refined system integration allow for reliable 24/7 operation, making it a cornerstone of modern aluminum foundry operations.

Whether producing structural chassis parts, suspension components, or other aluminum castings, the CPC 1600 delivers the ideal balance of speed, precision, and reliability—cementing its status as the world’s most sought-after counter pressure casting machine.

Features

- Counter Pressure Technology

- Multi Mold (6) Cavity Capable

- 96 Cooling Lines

- Siemens / Allen Bradley HMI

- Holding Furnace: 900kg – 1100kg

- Typical Parts : Chassis Components , Steering Knuckles , Control Arms, Brackets,

CPC 1600 to 1604

S-Mode CapableNoYesYes

CPC 1600 |

CPC 1601 |

CPC 1602 |

CPC 1603 |

CPC 1604 |

|

|---|---|---|---|---|---|

| Purpose | Standard | Automation | Quick Mold | + Furnace/Mold | + Productivity |

| Opening Stroke | 1.0 | 1.2 | 1.2 | 1.2 | 1.2 |

| Cylinders | Standard | Standard + | Duel + | Duel + | Duel + |

| Quick Mold Locks | Bolt | Bolt | Auto | Rohmfeld (Automatic) | Rohmfeld (Automatic) |

| Furnace Capacity | 900kg | 900kg | 900kg | 1100kg | 1100kg |

| PCD / Mold Size | Standard | Standard | Increased | 7500 | 7500 + |

For details on 1603 and 1604 machines contact CPC

Typical 1600 Parts

Chassis Components I Steering Knuckles I Control Arms

Need help finding the right machine?

If you would like more information about how a new CPC machine can bring your products to life, please contact us.