Quick Change Mold System

The CPC Quick Change Mold System is an advanced solution designed to dramatically reduce the time and complexity involved in changing molds during casting operations.

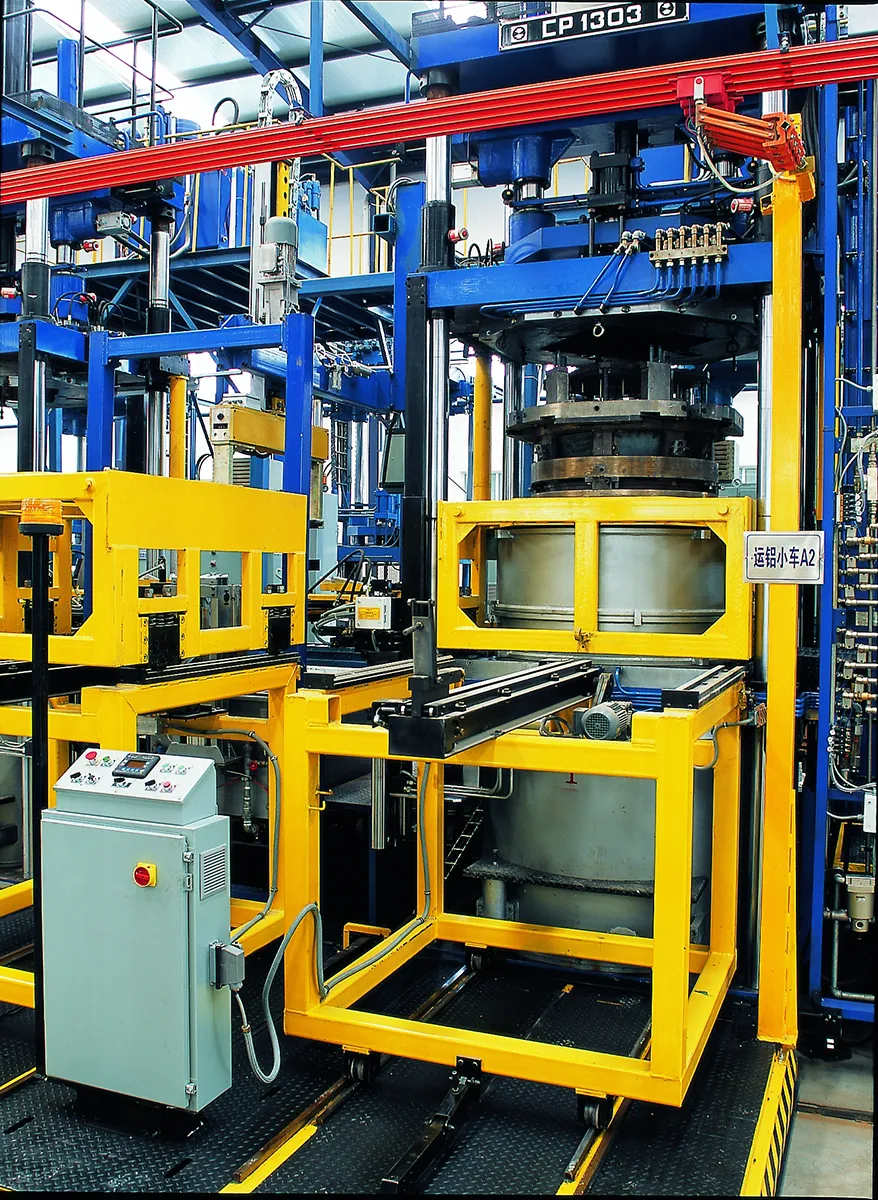

At its core, the system uses specially engineered quick mold change carts and automated mechanisms to streamline the process. In a typical setup, two carts are used: one holds a preheated mold ready for immediate use, while the other is positioned to remove the existing mold.

The system allows operators to release and secure molds with the push of a button, and features quick-connect cooling lines for rapid setup. This process, which traditionally could take up to an hour, can now be completed in less than ten minutes, especially in demanding foundry environments.

How It Works

Step 1: The empty (1st) cart is inserted into the machine to receive the old mold, which is lowered onto the cart and released automatically.

Step 2: The shuttle system then moves the (2nd) cart with the new, preheated mold into position.

Step 3: With another press of a button, the new mold is attached, and cooling lines are connected instantly through our manifold system, allowing production to resume.

Advantages

Advantage |

Description |

|---|---|

| Reduced Downtime | Mold changes in minutes, not hours |

| Increased Productivity | More cycles per shift, higher output |

| Enhanced Safety | Less manual handling, lower accident risk |

| Consistent Quality | Maintains optimal mold temperature and cooling |

| Labor Savings | Fewer operators needed, less specialized skill required |

| Greater Flexibility | Quick adaptation to new products or changes in demand |

| Cost Efficiency | Lower inventory and manufacturing costs |