CPC Holding Furnaces

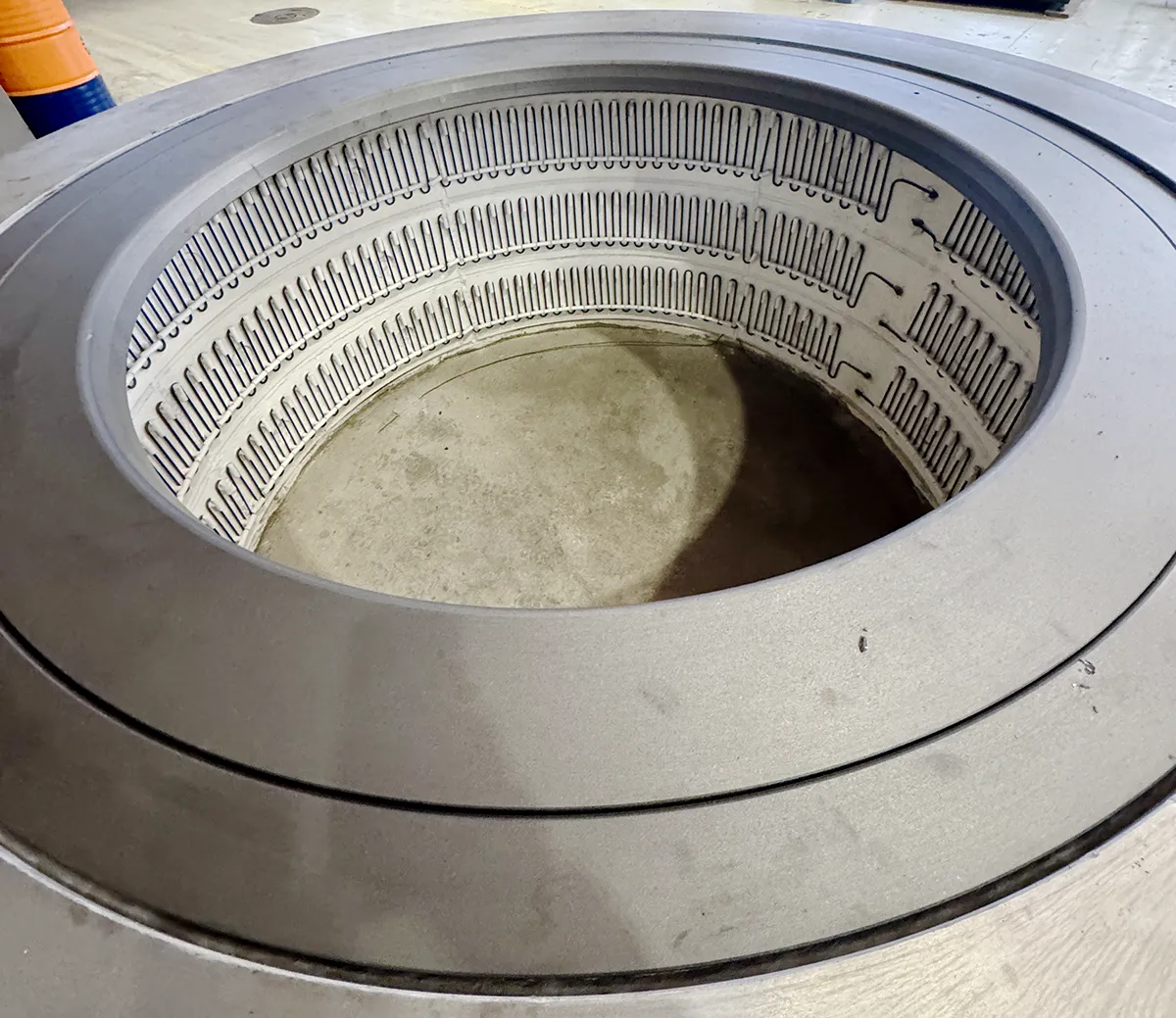

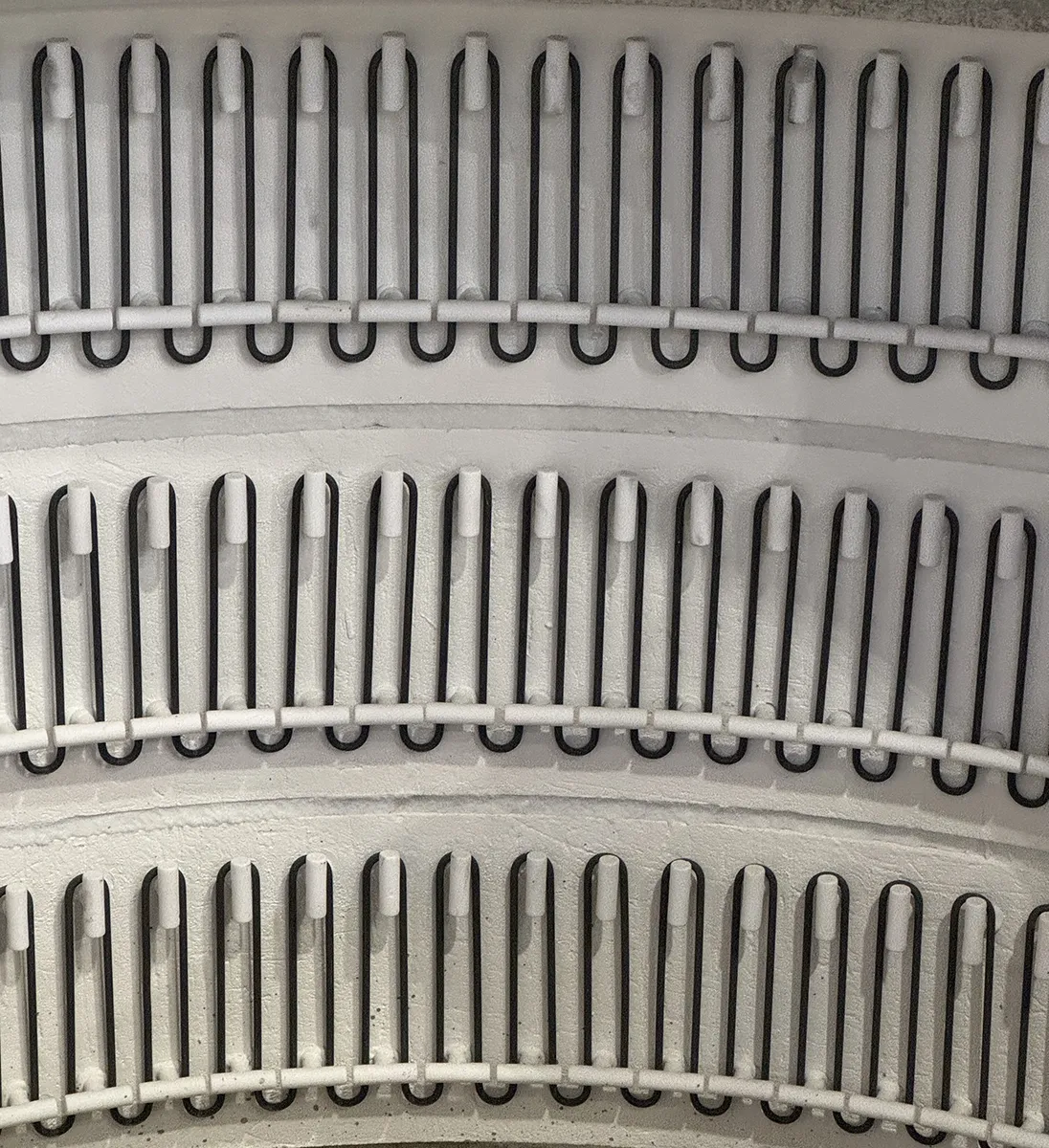

CPC (Counter Pressure Casting) holding furnaces are specially designed to maintain molten aluminum at precise temperatures and deliver it reliably to the casting process. These furnaces use a crucible to hold the molten metal which gives better metal quality. The crucibles are heated by electrical resistance elements, which offer highly accurate temperature control and efficient, clean operation.

Key Features

Crucible-Based Design: The molten aluminum is contained in a ceramic or metal crucible, which minimizes contamination and oxidation, ensuring high metal purity.

Electrical Resistance Heating: Heating elements surround the crucible and provide uniform, controllable heat. This method is energy-efficient, allows for precise temperature regulation, and eliminates combustion byproducts, resulting in a cleaner working environment.

Capacity: CPC holding furnaces are available in a range of sizes, typically from 500 kg up to 3,000 kg, accommodating various production needs.

Integration: These furnaces are often part of a shuttle system, allowing for rapid exchange and continuous casting operations with minimal downtime.

Advantages

Advantage |

Description |

|---|---|

| Superior Temperature Control | Electrical resistance heating ensures precise and stable temperature management for alloy quality. |

| Clean and Safe Operation | No open flames or combustion gases, reducing hazards and contamination. |

| High Metal Quality | Closed crucible design minimizes oxidation and hydrogen absorption for cleaner molten metal. |

| Operational Efficiency | Quick-change and shuttle integration allow rapid furnace replacement with minimal downtime. |

| Versatility | Suitable for a wide range of aluminum casting applications and production volumes. |