The CPC 1800 is a versatile counter pressure casting machine can handle both high-volume multi-cavity production and mid-sized structural castings with ease.

Whether you’re producing lightweight automotive components or larger, load-bearing parts, the CPC 1800 delivers superior mechanical properties, reduced porosity, and consistent quality. Its flexible configuration make it ideal for manufacturers seeking a reliable solution for a wide range of aluminum casting applications requiring precision and strength.

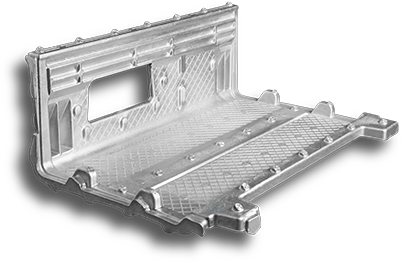

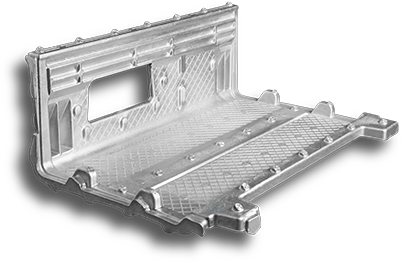

CPC 1800 C128

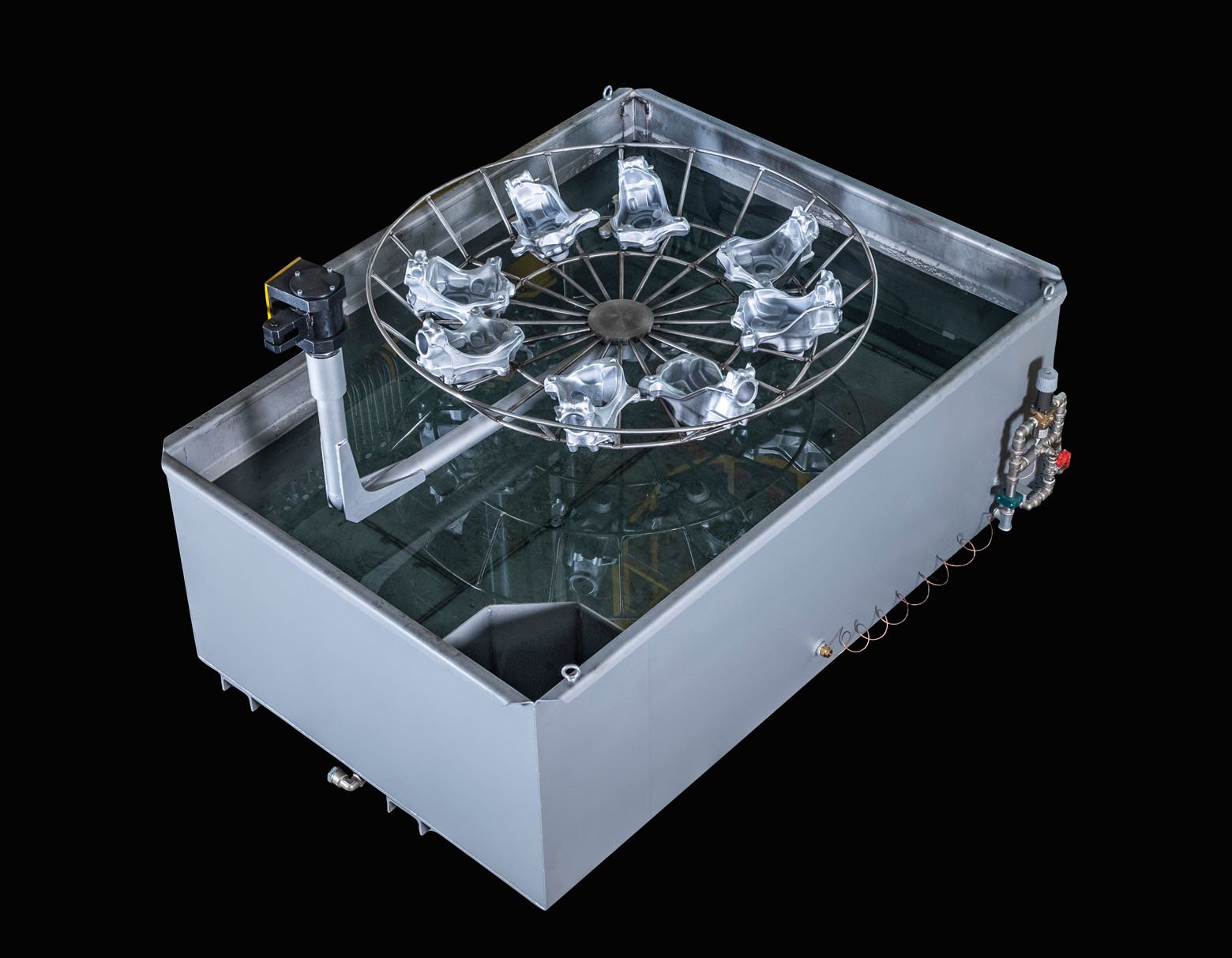

The CPC 1800 is the ultimate mid-sized casting solution for foundries seeking flexibility without compromising on quality or performance. Designed with dual-purpose capability, this machine excels in both multi-cavity production of smaller components and the casting of larger, more complex structural parts—making it a true workhorse for a wide range of aluminum applications.

More details

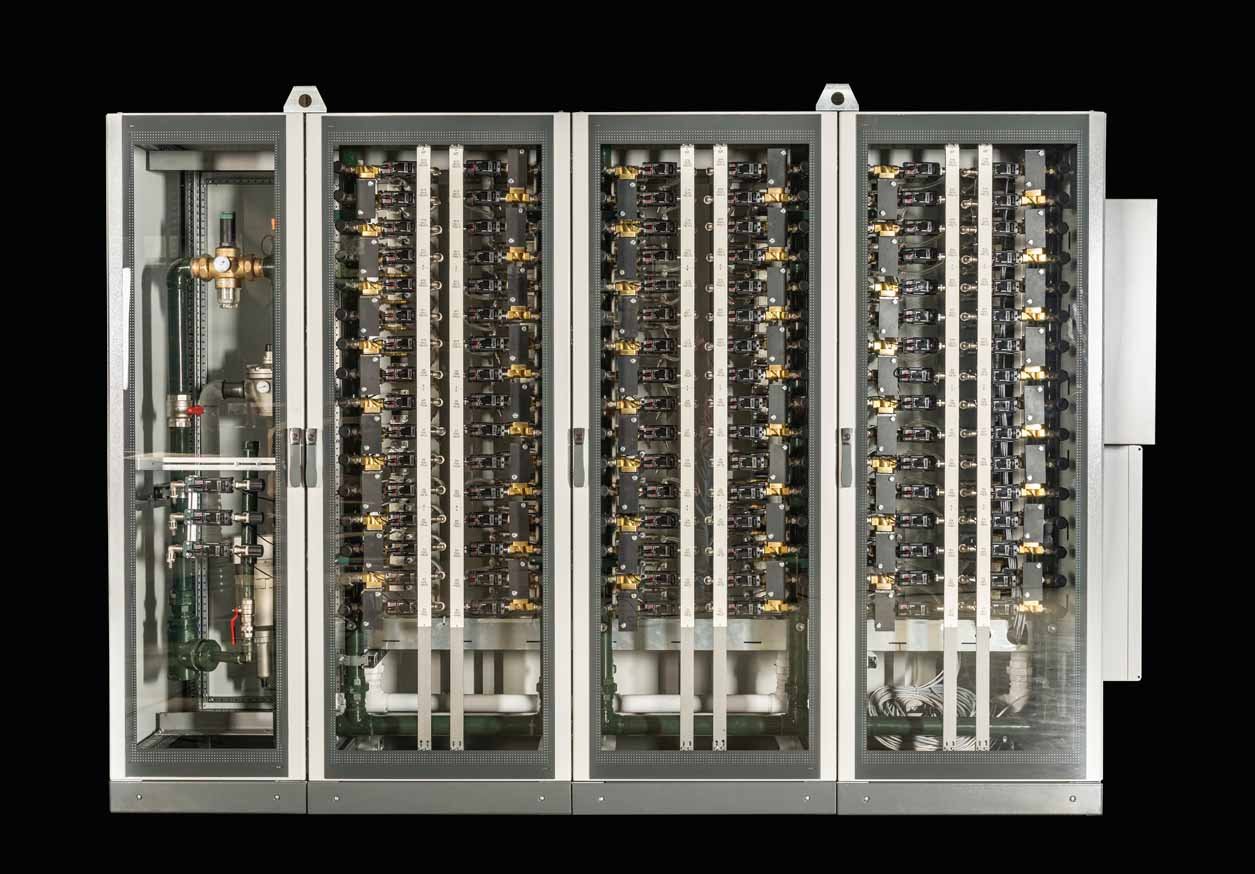

Whether you’re producing lightweight automotive parts in high volumes or single-cavity structural elements that demand strength and dimensional integrity, the CPC 1800 adapts effortlessly. Its mold interface can be configured with anywhere from 16 to 128 precision-engineered cooling lines, allowing customers to tailor the thermal management system to the exact requirements of each casting project. This adaptability ensures optimal cycle times, reduced scrap rates, and exceptional surface finish.

Like all CPC machines, the CPC 1800 is built on a foundation of industry-leading reliability, precision engineering, and foundry-proven technology. At its core is the advanced Counter Pressure Casting (CPC) process, which delivers superior mechanical properties, minimized porosity, and exceptional consistency across castings. This enables lighter-weight designs, enhanced structural performance, and improved post-processing results—all critical advantages in today’s competitive manufacturing environment.

The CPC 1800 is suitable for a wide variety of industries—including automotive, marine, medical, aerospace, electrical, and general industrial applications—making it a highly versatile investment for diverse production needs.

With a robust frame, modular control architecture, and seamless integration options, the CPC 1800 provides unmatched production value for operations looking to scale efficiently while maintaining the highest standards in aluminum casting.

Features

- Counter Pressure Technology

- Multi Mold (8) Cavity Capable

- 64-128 Cooling Lines

- Siemens/Allen Bradley HMI

- Furnace: 1200kg

- Small to Mid Sized Castings

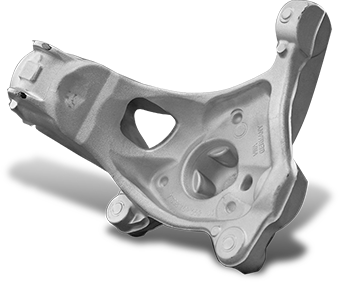

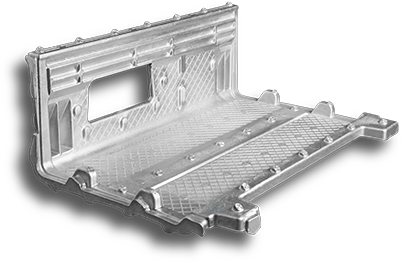

- Typical Parts : Chassis Components , Steering Knuckles , Control Arms, Larger Structural Components

Typical 1800 C128 Parts

Chassis Components I Steering Knuckles I Control Arms I Larger Structural Components

Need help finding the right machine?

If you would like more information about how a new CPC machine can bring your products to life, please contact us.